1. Why does stainless steel need to be cleaned?

Stainless steel is characterised by its high resistance to corrosion compared to other metals. The stainless steels used most in architecture are the AISI 304 austenitic steels, which include chromium and nickel, recommended for indoor use, and AISI 316, which includes, in addition to chromium and nickel, up to 2% molybdenum, giving it greater corrosion resistance in more aggressive environments, so it is recommended for outdoor use.

Stainless steel’s resistance to corrosion is due to a process called passivation, where the chromium in the alloy creates a protective layer that seals the stainless steel and protecting it from the elements. Accumulation of dirt can cause concentrations of corrosive substances that end up destroying the passive layer, but in the presence of oxygen from water or the air, the layer forms again instantly, even if it has been damaged. That is why it is necessary to clean stainless steel, to maintain that self-repairing mechanism, as it prevents critical concentrations of contaminants, such as sulphur dioxide, chlorides or ferrous contaminants.

2. What should I take into consideration based on the finishes?

Corrosion cannot develop unless a corrosive substance adheres to the surface. Smooth surface finishes, such as mirror polishes, are an obstacle that keep contaminants from adhering to the surface, so it helps make hand washing or natural rainwater more efficient. A rough surface, such as a satin finish, allows for greater accumulation of contaminants that make it harder to clean. As a result, a mirror polished surface reduces the risk of corrosion stains more than a satin finish. On the other hand, the polished finish tends to downplay fingerprints, so it is suited for indoor applications in which the component is exposed to contact with hands.

3. What maintenance and cleaning should I conduct outdoors?

When the stainless steel elements are installed outdoors, they may be exposed to more aggressive environments, so cleaning frequency, in this case, depends on the aesthetic requirements, the level of atmospheric corrosion (maritime atmospheres, industrial contaminants, air pollution, etc.), the amount of dirt and the accumulation of deposits. For moderate dirt, a regular cleaning is recommended every 6 to 12 months. For more dirt or for environments such as those described, regular cleaning is recommended every 3 to 6 months.

Pay special attention in coastal environments, as the saltpetre can corrode stainless steels. If the saltpetre accumulations on stainless steel absorb water, it will form a highly corrosive saline solution. Risk is high in the following conditions:

• Humidity and high temperatures.

• Fog or light rain

The wind brings salt from the sea inland: the areas within a radius of 8 to 16 km from the coastline are considered coastal. That is why we recommend AISI-316 over AISI-304.

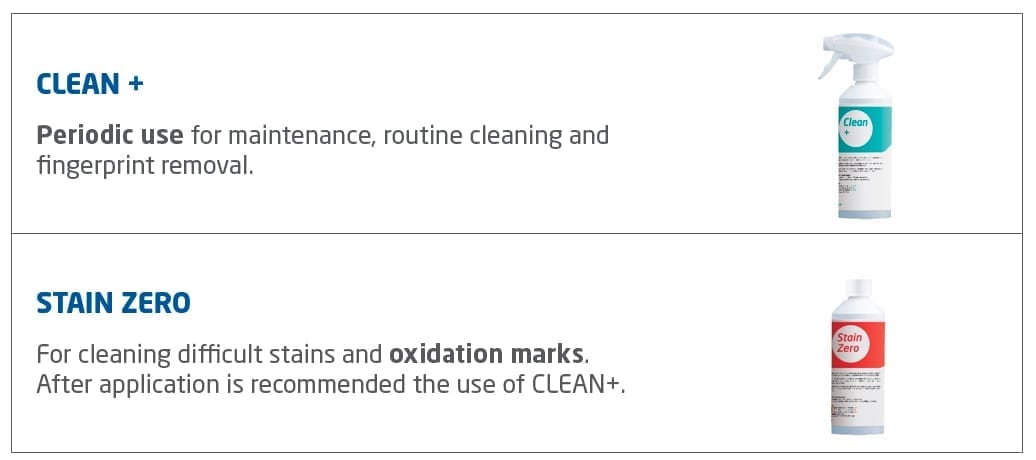

4. What cleaning methods are recommended?

We recommend using soft sponges or cloths and applying the cleaning product according to the instructions given, with the recommended temperatures and times. With regular maintenance, you will prolong the life of the metal, prevent problems of corrosion and ensure that the metal maintains a good appearance over time.

* If using water, dry well immediately. The use of deionised water is preferable.

5. What products should never be in contact with AISI 304 and AISI 316 steel?

• Carbon steel abrasives or hard objects

• Utensils previously used on non-stainless steels

• Chlorides, especially hydrochloric acid and hypochlorite bleaches

• Silver cleaning solutions

• Chlorinated or pool water

6. Is stainless steel magnetic?

Yes, there are families of magnetic stainless steels. For example:

• Ferritic stainless steels

• Martensitic stainless steels

• Duplex stainless steels

But there are also NON-magnetic families of stainless steel, such as:

• Austenitic stainless steels, including types AISI-304 and AISI-316.

However, austenitic steel may behave magnetically. This happens when:

1. The austenitic stainless steels are subjected to deformation processes (stretching during stamping, cutting), as they undergo a partial transformation of the austenite into martensite, which is magnetic.

2. Magnetism can also be detected in austenitic stainless steels hardened by lamination.

Relationship between magnetism and rusting

There is no correlation between magnetism and corrosion resistance in the applications in which stainless steel is commonly used.

Example:

304 stainless sinks: there is no magnetism at the bottom, where the material was hardly stretched. But a magnet easily detects the presence of martensite on the sides that were stretched more. A magnet can also detect magnetism on the edges of 304 stainless sheets. The deformation caused by cutting the sheet, such as at the drain, also turns the austenite into martensite.

References:

Technical Bulletin No. 15 September 2009 – Arcelor Mittal